Pure Aire was incorporated in January, 1963 in

order to create and produce contamination control

equipment, using at that time; the new laminar flow

technique. Since the beginning, Pure Aire has

created and produced units on a job shop basis

instead of a limited model production. Over the last

57 years that has remained true and is something

here at Pure Aire that we are proud of.

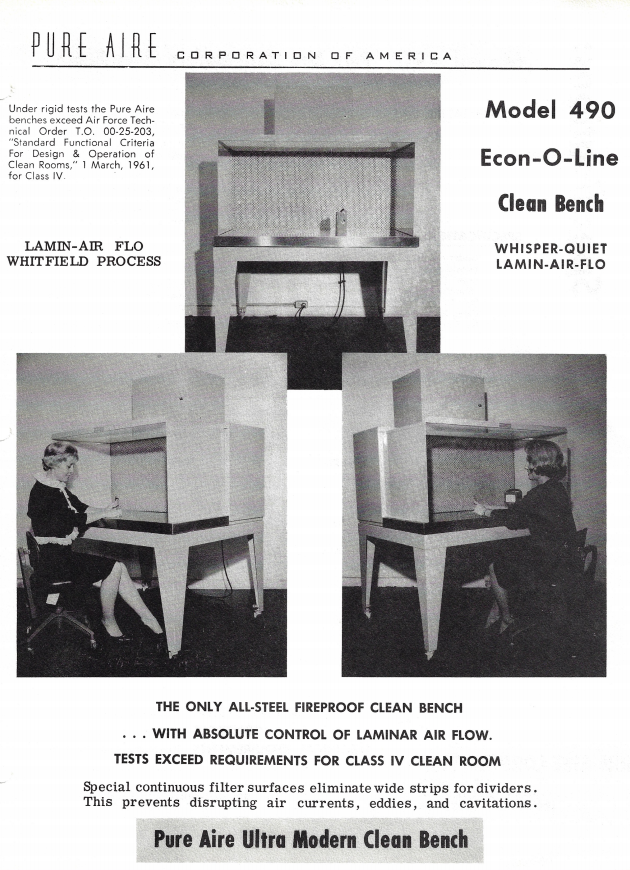

Pure Aire has been on the front lines of innovation in

this field. We have had many firsts in the industry

from the beginning of our journey. The laminar flow

tunnel concept and vertical flow work stations began

here, at Pure Aire. Along with fireproof all metal

construction and spring load filters for gasket

compensation. Pure Aire was also the first to build

units for hospitals, including developing a protype

for a patient isolation

bed for creating a

germ-free environment. We made a donation to the Burn Control

Center at Parkland Hospital in Dallas, Texas. This prototype allowed

for a sterile and clean environment that cannot be obtained by

conventional intervention. After this trial, Pure Aire was able to

develop and sell patient isolation units along with laminar flow

equipment for surgeries in hospitals.

Pure Aire continued to expand its reach, moving into the

pharmaceutical field as the FDA recognized laminar flow as a strategic and effective technique for

product filling and testing. Proceeding into food processing applications in order to deliver safer

products and longer shelf life; lowering unit costs and creating smaller old stock return. Over the

initial years, every year brought a new application which had been non-existent the year prior. As

time has passed, Pure Aire has been able to create standard items; still always manufactured

specifically for each job.

Our products at Pure Aire have always been

widely accepted and used. Pure Aire has

manufactured equipment for the U.S. Air Force,

Navy, NASA, and many major leading companies

in the United States. Pure Aire enjoys an

industry-wide reputation for providing superior

technical support of our equipment. Many of our

customers request equipment customized and

modified to satisfy a variety of specific needs.

Working in confidential and close cooperation

with your engineers and technicians, Pure Aire will

design the equipment that meets your most

exacting requirements. At Pure Aire, our in-house

manufacturing capabilities control total equipment

quality. This capability, coupled with our propriety

fabrication procedures and techniques, gives us

the versatility and maximum flexibility required to

customize equipment to virtually any

specifications.

Pure Aire, over the years, established a well-known reputation for our ongoing commitment to

provide quality products at reasonable prices. It’s a well-deserved reputation confirmed by our

history of over 57 years in business and an ever-expanding roster of satisfied customers. We

cordially invite you to join them.